When you say RJC, you say craftsmanship. The teams in the shops prefer to lead rather than follow when it comes to applying new modern techniques. From drone inspections to the use of borescopes, it often starts in the shops. Each workshop has a unique identity, but collaboration is frequently necessary to deliver the highest quality products for the customer.

Shops

Shops at Regional Jet Center

RJC is a dynamic organization, and the dedicated mechanics from various workshops play a crucial role within it. What sets them apart? Craftsmanship and teamwork. The Shop Mechanics are indispensable for the maintenance operation. From working on engines to repairing almost invisible aircraft components, at the RJC, you can explore a wide range of opportunities!

Engine Shop

In the Engine Shop, they simply put their skills to work on aircraft engines. They specialize not only in repairs and maintenance but also in conducting borescope inspections. As a team, they excel in the use of this advanced technology. RJC is the only aircraft maintenance company in the Netherlands that applies this technique at a high level!

Sheet Metal Shop

Lightning strikes, bird strikes, or hailstones. An aircraft endures a lot during its flight, resulting in significant damage. Fortunately, there is no shortage of craftsmanship in the Sheet Metal Shop. Various parts of the aircraft, from aluminum to composite materials, are meticulously repaired. Do they spend the entire day behind the workbench? Certainly not! Damages are also addressed directly on, under, or near the aircraft.

Interior Shop

In the Interior Shop, they primarily carry out meticulous repairs on composite materials. But they also handle tasks such as restoring cockpit and cabin seats or maintaining cargo nets. These mechanics are well-versed in traditional craftsmanship and are certainly not afraid to experiment with innovative methods.

Tooling & Equipment

Tooling & Equipment creates essential tools for aircraft maintenance, such as nitrogen carts. They also annually inspect all electrical devices and meticulously maintain the existing tools.

Paint Shop

In the Paint Shop, colorful details come to life. Within this shop, they primarily work with composite aircraft paneling (interior and exterior) and engage in both interior and exterior aircraft decal work. They are also quite skilled with a paintbrush, whether they are repairing damages in the shop or applying a coat of paint to the aircraft in the hangar.

ERI Shop

A steady hand? The mechanics at ERI certainly have it! Precision and reliability are the focus here. At ERI, they repair all kinds of electronic devices... coffee makers, boilers, ovens, in-cabin batteries, and even cable looms.

''We are specialists and want to become the best at what we do. Fortunately, we have all the space for that.''

Meet your (future) colleagues

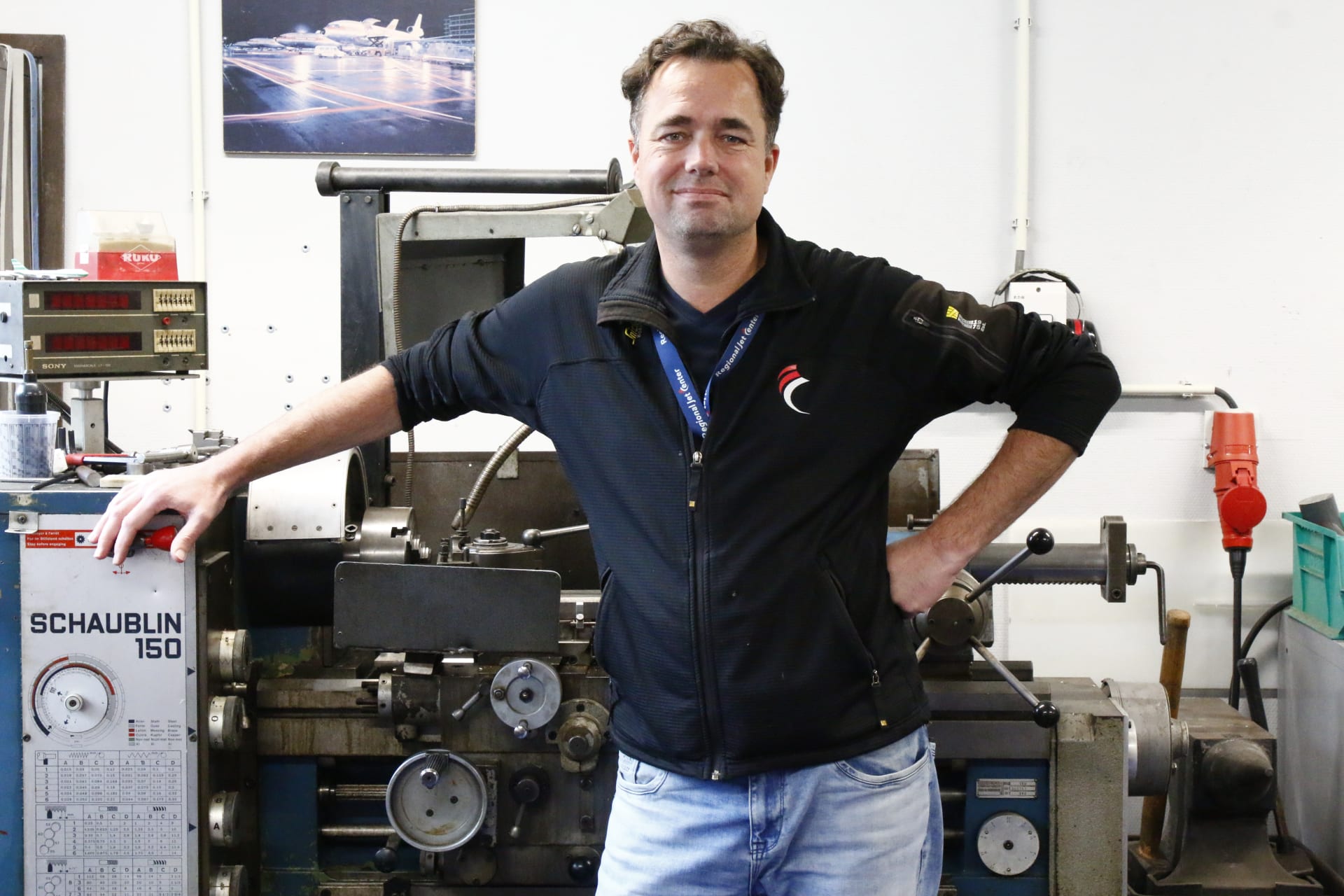

Hans

Team Manager

Kees

Paint shop

Niels

Tooling & Equipment mechanic

Mitchell

Sheet Metal worker

Jop

Engine Shop Mechanic

Thomas

Engine Shop Mechanic

Bram

Sheet Metal Worker

Rix

Stagiair sheet metal work

Open positions

Benefits

Shifts

You work only day and evening shifts

40 days off

27 vacation days + 13 ADV (Additional Days Off) days per year

Bonuses

Salary, Shift allowance, year-end bonus, holiday allowance, and an annual profit-sharing

Stand-by flying

You can fly at a reduced rate on all KLC (KLM Cityhopper) and KLM flights

Get in touch

Boutaina Benouar

Recruiter 06 39 68 02 79